Scenario: HETAC for Commercial Buildings

A major firm in Sydney’s west is looking at expanding it’s office space with the addition of a new wing having a total area of 1,000m2. Office hours are 9am to 6pm weekdays.

The ‘LoadSmart Business Plan’ offers electricity at rates of 24.97c/kWh, 13.42c/kWh and 7.26c/kWh for peak (2pm-8pm), shoulder (7am-2pm and 8pm-10pm) and off-peak (all other times), respectively. A peak capacity charge of 12.5c/kW/day is also applicable.

A chilled beam system is installed with a supply/return temperature of 14°C/17°C. The maximum daily and overnight ambient temperatures are 43°C and 15°C, respectively.

Select a suitable water-chiller and PCM required and estimate the associated power/cost savings by implementing a HETAC thermal storage system.

Water-Chiller

Assuming a total sensible heat load of 130W/m2, the daily average cooling capacity for the new wing will be 130W/m2 x 1,000m2 = 130kW

The water-chiller chosen to fulfil this cooling requirement is supplied by HL Cooling Pty. Ltd. and has the following specifications*:

Model No: RAE1352K

Nominal** Cooling Capacity: 131kW

Nominal** Compressor Input Power: 4 x12.3kW each

Energy Efficiency Ratio: 2.23

Condenser Fans: 2 x 2kW each

Water Pump Power: 5.5kW

* https://www.hlcooling.com.au/

** Nominal conditions assume Water Outlet Temperature (WOT) = 7°C and Ambient Temperature (AT) = 32°C.

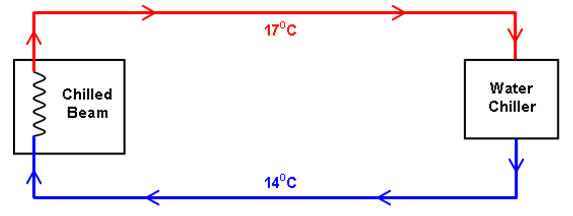

Conventional Air-Conditioning System (without PCM)

A simplified schematic of the conventional air-conditioning system is shown below:

Cooling capacity @ 43°C AT / 14°C WOT

1.27 x 0.85 x 131kW = 141kW

Compressor input power @ 43°C AT / 14°C WOT

1.102 x 1.3 x 4 x 12.3kW = 70.5kW

Total input power:

70.5kW (compressors) + 4kW (fans) + 5.5kW (pump) = 80kW

Energy efficiency ratio:

141kW / 80kW = 1.76

Daily energy consumption for 9 hours (daytime):

9h x 80kW = 720kWh

Annual cost of electricity:

260 days x [($0.125/kW/day x 80kW) +

(5h x 80kW x $0.1342/kWh) +

(4h x 80kW x $0.2497/kWh)] = $37,332

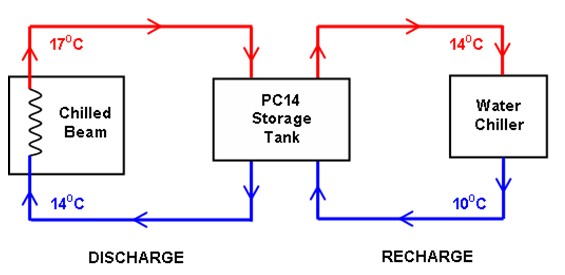

HETAC Thermal Storage System (with PCM)

The best choice would be to use PC14 as the temperature leaving the PCM storage tank will closely match the chilled beam supply temperature of 14°C. PC14 has a latent heat of fusion of 145kJ/kg and an onset melting temperature of around 10°C.

A simplified schematic of the HETAC thermal storage system is shown below:

Total storage capacity for 9 hours:

130kW x 9h = 1,170kWh

Quantity of PC14 required to store 1,170kWh of energy:

1,170kWh x 3,600[s/h] / 145kJ/kg = 29,049 kg

Total number of panels required:

29,049kg / 4.3kg per panel = 6,756 panels

Cooling capacity @ 15°C AT / 10°C WOT:

1.1 x 1.19 x 131kW = 171kW

Compressor input power @ 15°C AT / 10°C WOT:

1.045 x 0.688 x 4 x 12.3kW = 35.4kW

Total input power:

35.4kW (compressors) + 4kW (fans) + 5.5kW (pump) = 44.9kW

Energy efficiency ratio:

171kW / 44.9kW = 3.81

Time to recharge PCM’s:

(130kW/171kW) x 9h = 6.8h

Daily energy consumption 9 hours (daytime) + 6.8 hours (overnight):

(9h x 5.5kW) + (6.8h x 44.9kW) = 355kWh

The annual cost of electricity will be:

260 days x [($0.125/kW/day x 5.5kW) +

(6.8h x 44.9kW x $0.0726/kWh) +

(5h x 5.5kW x $0.1342/kWh) +

(4h x 5.5kW x $0.2497/kWh)] = $8,330

Annual cost savings:

$37,332 – $8,330 = $29,002

$29,002 / $37,332 = 77.7%

Daily energy savings:

720kWh – 355kWh = 365kWh

365kWh / 720kWh = 50.7%

This simple example illustrates that a cost saving >77% and energy saving >50% is achievable by implementing a HETAC thermal storage system.

‘Beat-the-Peak’

A similar package can be designed to ‘Beat-the-Peak’ loading between 2pm-6pm (4 hours) and would only need to be:

(4h / 9h) x 29,049 kg = 12,911 kg (3,003 panels)

Daily energy savings during peak period:

(80kW – 5.5kW) x 4h = 298kWh

298kWh / (80kW x 4h) = 93.1%

Annual cost savings during peak period:

$23,375 – $4,184 = $19,191

$19,191 / $23,375 = 82.1%

Further cost savings >82% and energy savings >93% can be achieved by implementing a HETAC thermal storage system solely during peak times to ‘Beat-the-Peak’ when energy costs are at their highest.